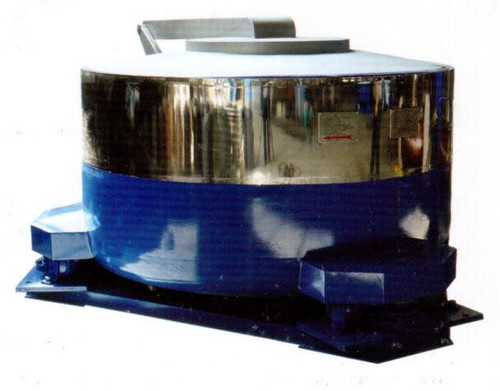

Patented Hydro Extractor

Product Details:

- Manufacturing Year 2019 Years

- Applicable Material SS

- Type Hydro Extractor

- Voltage 220-240 Volt (v)

- Click to View more

X

Patented Hydro Extractor Price And Quantity

- 1 Set

Patented Hydro Extractor Product Specifications

- 2019 Years

- 220-240 Volt (v)

- SS

- Hydro Extractor

Patented Hydro Extractor Trade Information

- SHANGHAI

- 10 Set Per Month

- 45 Days

- Contact us for information regarding our sample policy

- All India

Product Description

Featrues:

- Lower water content, and the cotton of 43% (32s-40s)

- Dehydration without deformation, and no contact between the surface of bobbin yarn and its inner wall, so the surface of bobbin yarn will not wear out

- One hydro extractor equipped with a suspension cage, hanger and movable trolley can be used as two machines, greatly improving the utilization of equipment and reducing the labor intensity of workers in loading and unloading the cage

- No dropping of head occurs to the bobbin yarn when unwinding

- Now it can be one-time loading 156 bobbins

- The whole dehydration process takes only 12.5 minutes with special motors (from start to stop)

- The motor control using the variable frequency system

- The variable-frequency energy-consumed braking used for the brake of dehydrator

- Motor power: 15kw

- Efficiency: Loading yarn Put the suspension cage into the dehydrator for dehydration Hang out the suspension cage after dehydration Put the suspension cage back into the dehydrator

- Cycle through the whole process (after being skilled, it takes 15-16 minutes each time), so in one hour, it can be dehydrated four times (namely 600 kg of yarn). Based on 12 hours is one shift to calculate, theoretically, this machine can dehydrate 7. 2 tons of yarn. Now the output of the customer under the actual operation is more than 6 tons/12 hours.

Enter Buying Requirement Details

Other Products in 'Dyeing Machine and Auxiliary Equipment' category

|

WUXI HONGHAO INTERNATIONAL TRADE CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese