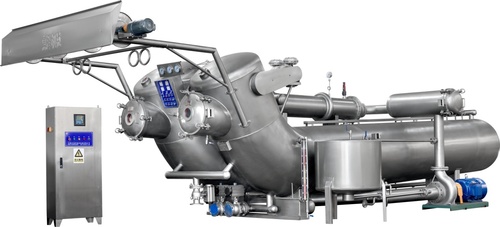

Cone Yarn Dyeing Machine

Product Details:

- Fabric Type yarn packages, zipper tapes, small width fabrics and warn beams

- Voltage 380 Watt (w)

- Manufacturing Year 2018 Years

- Type Dyeing Machine

- Click to View more

Price And Quantity

- 1 Set

Product Specifications

- 2018 Years

- Dyeing Machine

- 380 Watt (w)

- yarn packages, zipper tapes, small width fabrics and warn beams

Trade Information

- SHANGHAI

- 10 Set Per Month

- 45 Days

- Contact us for information regarding our sample policy

- In bulk and assembly at site packing with plastic foam in steel frame export wooden box

- All India

- CE

Product Description

Holding a highly reputed and trusted market standing, we are engaged in manufacturing and supplying Cone Yarn Dyeing Machine. We manufacture this machine under the guidance of expert supervisors using high quality materials. This machine is used for dyeing yarn at high temperature and high pressure. The machine has a vertical cylinder type structure. Cone Yarn Dyeing Machine is applicable for yarn packages, zipper tapes, small width fabrics and warn beams. We offer this machine at cost effective prices to clients.

Features:

- Coil type heat exchanger

- Pneumatic cylinder lift door

- Hydraulic safety locking for door

Details:

- The machine has a vertical cylinder type structure

- The working capacity varies from 5KG, 10KG, 20KG, 50-75KG, 100 up to 125KG

- The working temperature is around 130

- Max working pressure of the machine is 0.3 Mpa

- Bath ratio is 1:5

- The machine uses a coil type heat exchanger for heating and cooling

When the heating steam pressure is around 0.4 Mpa, within 40 mins the temperature of the dyeing liquid rises from 20 to 130 while when the cooling water pressure is around 03. Mpa and the temperature of water is 20, the temperature of the dyeing liquid falls from 130 to 80 in 40 mins.

Recycling method dyeing liquid: Both the positive as well as negative recycling of the dyeing liquid will be manoeuvred through the cylinder with the help of switching devices located inside the centrifugal pump

Sealing method of boiler body: Use of a self-sealing type rubber adhesive tape depends on the pressure built inside the boiler which in turn makes the rubber adhesive tape closer and attached to the flange surface of the mouth of the boiler mouth in order to realize the sealing

- Product: equipment

- Material Capabilities: stainless steel sus321

- Condition: New

- Certification: CE

- Packaging Details: seaworthy and strong package

- After-sales Service Provided: Engineers are available to provide services of the machinery overseas

- Delivery Detail: 45 working days after 30% of the total amount is received as deposit

- Minimum Order Quantity: 1 set

- FOB Price: US$-/set

- Port: SHANGHAI, CHINA

- Supply Ability: 10 Sets per Month

- Payment Terms: L/C; D/P; T/T; Western Union

Other Products in 'Dyeing Machine and Auxiliary Equipment' category

|

WUXI HONGHAO INTERNATIONAL TRADE CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese